| Registro

The manufacturing industry has experienced significant changes over the past few decades, with rapid advancements in technology driving new methods and possibilities. Among the most impactful developments are precision metal fabrication, 3D printing services, and custom CNC machining. But how are these technologies transforming the industry, and what role do they play in the future of manufacturing? Let’s explore how each of these services is making a significant impact

Precision Metal Fabrication: Unlocking the Future of High-Quality Metal Parts

Precision metal fabrication involves the process of cutting, bending, welding, and assembling metal structures with high accuracy. The precision aspect is vital in industries like aerospace, automotive, and medical equipment, where even the slightest deviation in measurements can have serious consequences.

Advances in fabrication techniques, such as laser cutting and waterjet cutting, allow manufacturers to create highly complex metal parts with tight tolerances. The ability to fabricate custom metal components with precision is driving innovation across industries, ensuring that the highest standards of quality and performance are met.

With the rise of automation and robotic technology, precision metal fabrication is becoming faster, more cost-effective, and more efficient. As manufacturing continues to demand faster production cycles and higher-quality products, precision metal fabrication will remain a key technology in the industry.

3D Printing Services: Revolutionizing Prototyping and Production

In recent years, 3D printing, or additive manufacturing, has gained tremendous traction across various sectors, allowing manufacturers to create complex parts directly from digital models. What makes 3D printing so valuable is its ability to produce intricate geometries and low-volume production runs that would be nearly impossible or cost-prohibitive with traditional methods.

3D printing services offer immense flexibility, especially for prototyping. Designers and engineers can quickly produce prototypes, test them for fit and function, and make adjustments without incurring significant costs or delays. This rapid prototyping capability has enabled more agile product development cycles and enhanced innovation across industries like aerospace, healthcare, and consumer goods.

Furthermore, 3D printing is allowing manufacturers to create parts using specialized materials, including advanced metals, ceramics, and plastics. This opens up new possibilities for industries requiring complex and high-performance components that traditional methods could not produce.

Custom CNC Machining Services: Tailoring Precision to Your Needs

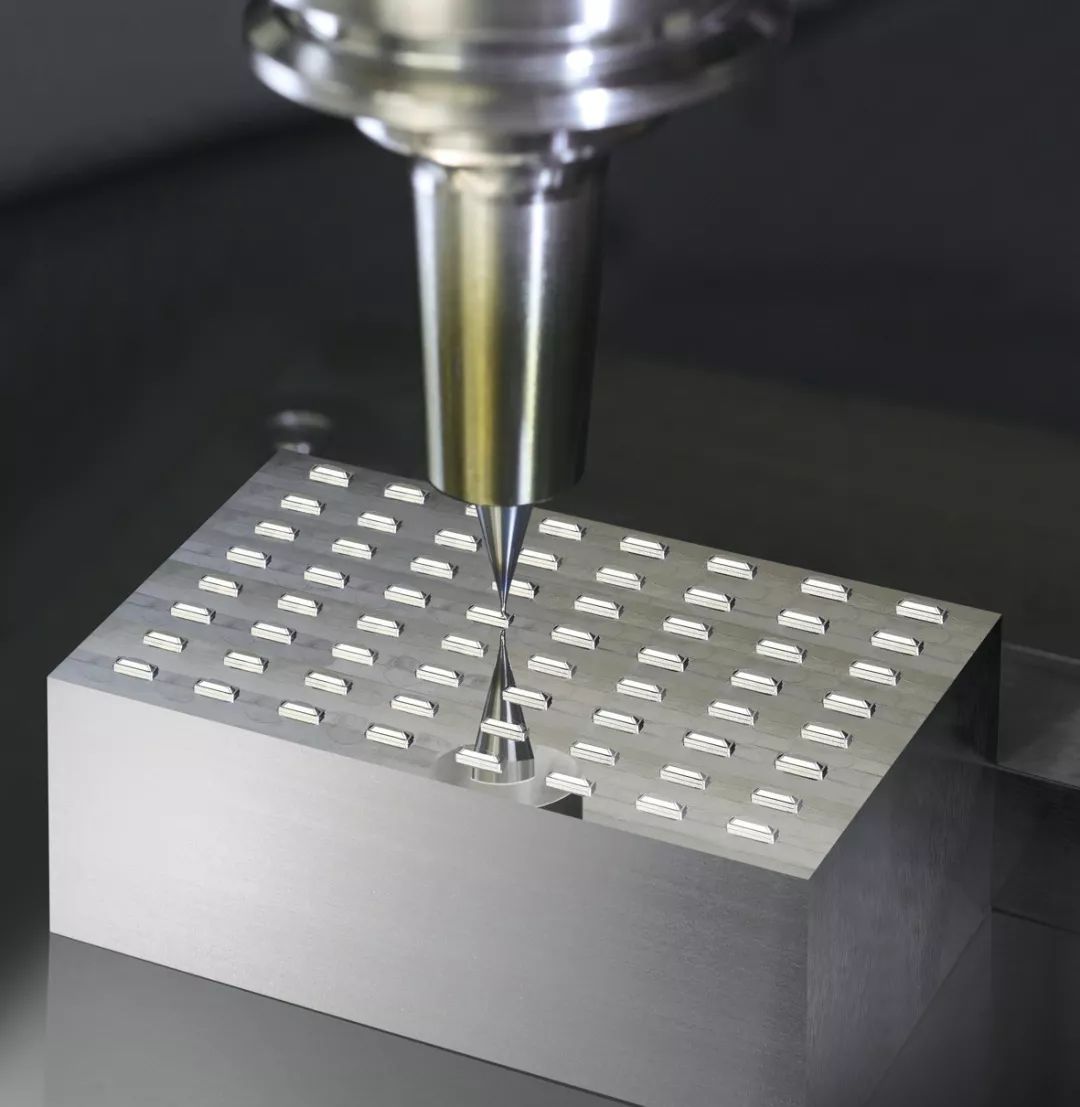

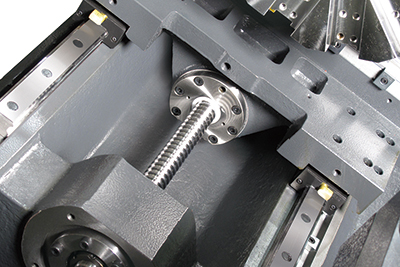

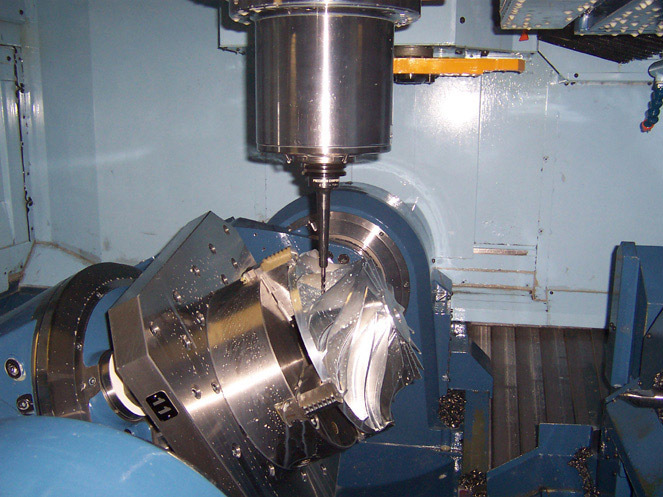

CNC (Computer Numerical Control) machining remains one of the most popular methods for producing high-precision parts. By using computer programming to control machine tools, custom CNC machining enables manufacturers to create parts with unparalleled accuracy, all while reducing human error and improving repeatability.

One of the standout advantages of custom CNC machining is its versatility. Whether it's for small custom parts or large-scale production, CNC machines can produce a wide range of components, including complex shapes and tight tolerances, from a variety of materials such as metals, plastics, and composites. The ability to adjust machine settings to fit specific requirements allows manufacturers to tailor the production process to individual customer needs, making CNC machining an ideal solution for a variety of industries.

In addition to its high precision and versatility, custom CNC machining is highly efficient. Automation and advanced programming capabilities enable manufacturers to optimize production cycles, minimize material waste, and reduce costs.

.

The Intersection of Precision Metal Fabrication, 3D Printing, and CNC Machining

While each of these technologies—precision metal fabrication, 3D printing, and custom CNC machining—offers its unique set of benefits, their true potential is realized when they work together. Manufacturers increasingly combine these technologies to deliver complex solutions that meet specific customer requirements.

For example, 3D printing can be used for rapid prototyping, allowing manufacturers to design and test parts quickly before transitioning to CNC machining for mass production. Meanwhile, precision metal fabrication can be used for final adjustments or specialized finishes to meet exact specifications.

The combination of these advanced manufacturing technologies provides greater flexibility, speed, and quality control in production, ensuring businesses can stay competitive in a fast-paced market.

What’s Next for These Technologies?

As these technologies continue to evolve, we can expect even greater synergies between precision metal fabrication, 3D printing, and custom CNC machining. Advancements in automation, AI, and material science will drive further innovations, allowing manufacturers to produce even more complex and durable parts with greater efficiency.

The future of manufacturing is undoubtedly intertwined with these cutting-edge technologies. With precision, customization, and efficiency at the forefront of industrial development, precision metal fabrication, 3D printing services, and custom CNC machining will continue to shape the way products are designed and produced