| Registro

Due to the high requirements for processing semiconductor equipment parts, in order to complete the processing of multi-surface, complex internal cavities, and parts with numerous side features with high precision at one time, our factory introduced a Japanese imported MAZAK 5-AXIS CNC machining center in 2022. The maximum load capacity is 3000KG, the maximum processing diameter is 1700mm, the maximum processing height is 1600mm, and the positioning accuracy can reach ±0.002mm. Below are the applications of our 5-axis CNC in the processing of key semiconductor equipment components such as vacuum conversion chambers, impellers, and vacuum sputtering chambers.

Advantages of 5-axis CNC Technology

The 5-axis CNC machining center has significant advantages over traditional 3-axis equipment.

1) Ensuring positioning accuracy: Complex geometries can be completed in one setup, reducing repetitive positioning errors.

The positioning accuracy can reach ±0.002mm, meeting the strict requirements of semiconductor equipment.

2) Surface processing capability: Surface roughness of Ra < 0.4μm

3) Improving processing efficiency: Optimizing the tool path to enhance processing efficiency.

4) Multi-angle processing capability: Completing complex side features and complex internal cavity processing.

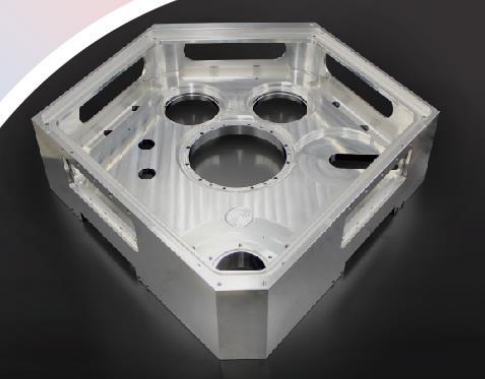

5 Application of Vacuum Conversion Chamber Processing

The vacuum conversion chamber, as a key component connecting different vacuum environments in semiconductor equipment, presents processing challenges as follows:

1) Complex internal structure: 5-axis CNC enables integrated processing of complex flow channels.

2) High sealing requirements: Flatness requirement is <0.01mm/m, and 5-axis processing can ensure the accuracy of the joint surface.

3) Processing of special flanges: Multiple-angle flange surfaces can be completed in one setup.

4) Thin-walled structure: 5-axis dynamic processing reduces the risk of deformation.

In terms of processing techniques, we use high-stiffness cutting tools for rough processing,

and adopt a fine processing strategy with small cutting depth and high rotational speed. Other special curved surfaces are processed using ball-end tools in 5-axis continuous linkage.

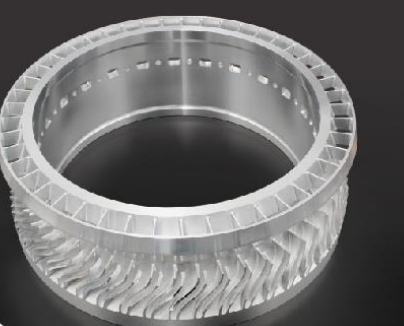

Key technologies for the processing of impellers

The semiconductor vacuum pump impeller has the following features:

1) Complex three-dimensional curved blades

2) Strict aerodynamic performance requirements

3) Dynamic balance requirements under high rotational speeds

5-axis CNC processing strategy for blade-like components:

1) Precision leaf forming: 5-axis linkage ensures the accuracy of the leaf profile

2) Complete rotor disc processing: The entire rotor is directly manufactured from the raw material

3) Dynamic balance control: Precise processing reduces the need for subsequent balance adjustments

4) Surface polishing: The 5-axis machine tool can directly complete mirror-like processing

Challenges in the processing of vacuum sputtering chambers

1) The main processing challenges faced by the vacuum sputtering chamber:

2) Large-scale precision processing: Chambers with diameters of over 2 meters

3) Processing of special materials: Stainless steel, aluminum alloy or titanium alloy

4) Processing of cooling channels: Complex embedded cooling passages

5) Ultra-high vacuum sealing: All joint surfaces need to be precisely processed

Processing strategies:

1) Segmented processing of large cavities: Ensuring assembly accuracy through precise positioning of benchmarks

2) Optimization of cutting for special materials: Customizing cutting parameters for different materials

3) Internal cavity polishing: Surface treatment of inaccessible areas is completed by a 5-axis machine tool

4) Integration of multiple processes: Drilling, tapping, milling, etc. are all completed in one setup

In recent years, our MAZAK 5-AXIS CNC machining center has become a core equipment for semiconductor equipment manufacturing. In the processing of key components such as vacuum conversion chambers, impellers, and vacuum sputtering chambers, the 5-axis technology not only improves processing accuracy and efficiency, but also enables the manufacture of complex geometric shapes that are difficult to achieve with traditional methods, meeting the processing requirements of customers.