| Registro

When it comes to manufacturing precision components, sheet metal fabrication and custom aluminum extrusion are two crucial processes that offer incredible versatility and strength. Whether you are designing a new product or need parts for an existing one, these services can provide tailored solutions that meet your specific needs. Here's a look at why you should consider utilizing these services for your next project.

Advantages of Sheet Metal Fabrication Services

Sheet metal fabrication is a process that involves cutting, bending, and assembling thin metal sheets to create functional parts or structures. The process offers flexibility in terms of material selection and design, allowing manufacturers to produce custom parts that meet the exact specifications required by industries such as automotive, aerospace, and electronics.

One key advantage of sheet metal fabrication is its ability to produce large quantities of parts quickly and efficiently. CNC machines and laser cutting technology used in sheet metal fabrication ensure high precision, reducing the risk of errors. The process is also cost-effective, especially for projects that require mass production. Furthermore, sheet metal can be easily combined with other materials to create composite parts with enhanced properties.

Custom Aluminum Extrusion Services: Perfect for Complex Designs

Custom aluminum extrusion is another highly versatile process that allows manufacturers to create a wide range of profiles from aluminum. The process involves pushing aluminum through a die to form various shapes, including rods, tubes, and custom profiles that can be used in many applications, from construction to consumer products.

One of the key benefits of custom aluminum extrusion is its ability to create lightweight yet durable parts with excellent strength-to-weight ratios. Aluminum is also highly resistant to corrosion, making it an ideal choice for projects that require components exposed to the elements. With custom dies, manufacturers can create profiles that match specific design needs, making aluminum extrusion perfect for complex, unique designs that cannot be achieved using standard shapes.

Aluminum Extrusion CNC Factory: Combining Precision with Customization

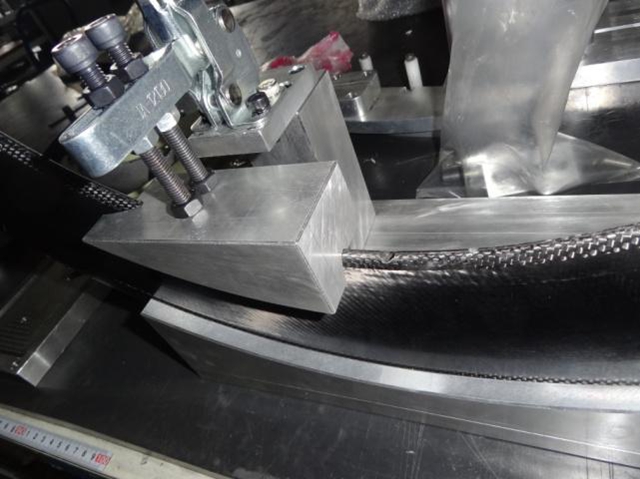

For even greater accuracy and customization, an aluminum extrusion CNC factory can provide additional benefits. CNC (Computer Numerical Control) machining allows for the precise cutting, shaping, and finishing of aluminum extrusions to meet specific tolerances. CNC machines operate with incredible precision, which is ideal for applications that require tight tolerances and high-quality finishes.

An aluminum extrusion CNC factory provides the flexibility to work with a range of aluminum alloys, giving manufacturers the ability to produce parts for a variety of industries, including automotive, aerospace, electronics, and more. Whether it’s precision drilling, milling, or engraving, CNC machines can work with custom profiles and apply intricate details to the final product.

Why These Services Are Essential for Your Projects

Integrating sheet metal fabrication, custom aluminum extrusion, and CNC machining allows manufacturers to produce parts that are not only strong and durable but also highly customizable to meet specific design and functionality requirements. These processes work together to offer an efficient, cost-effective way to create high-quality parts for industries where precision and performance are paramount.

With their ability to handle both simple and complex designs, these services are crucial for any manufacturing project that requires unique components or large-scale production. Whether you're looking for precision parts for industrial applications or custom-designed components for consumer products, sheet metal fabrication, custom aluminum extrusion, and CNC machining services provide the flexibility and efficiency necessary to meet your goals.

By choosing the right combination of these services, manufacturers can ensure that their parts are produced with the highest standards of quality and accuracy, setting them up for success in today’s competitive market.