| Registro

Date: February 10, 2025

Rapid Growth Fueled by Automation and Sustainability

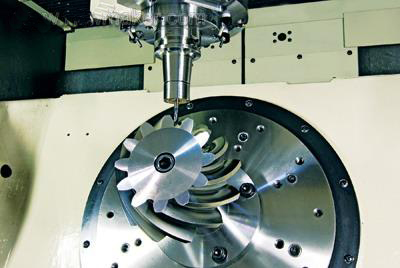

The global CNC (Computer Numerical Control) machining industry is undergoing a transformative phase, driven by advancements in smart manufacturing and a global push toward sustainability. According to a 2024-2029 market analysis by Zhongdao Taihe 4, the sector is projected to grow at a 6.8% CAGR, reaching $142 billion by 2029. Key innovations such as AI-driven predictive maintenance, 5G-enabled real-time monitoring, and energy-efficient machining processes are reshaping production landscapes.

Sustainability Initiatives Take Center Stage

Under tightening EU carbon regulations, CNC manufacturers are adopting green machining strategies:

Recyclable Coolants: New biodegradable fluids reduce environmental impact by 60%.

Energy Recovery Systems: Regenerative braking in CNC spindles recaptures 15% of energy.

Lightweight Aluminum Alloys: Demand for eco-friendly aerospace-grade aluminum (e.g., 7075-T6) has surged by 35%, driven by Boeing and Airbus’ net-zero pledges

Challenges and Opportunities

While automation reduces labor costs, the industry faces a 20% skilled-worker shortage globally. To address this, vocational training programs integrating VR-based CNC simulations have expanded in India and Mexico. Meanwhile, geopolitical tensions continue to disrupt supply chains, with titanium and rare-earth metal prices fluctuating by ±18% monthly

Quotes from Industry Leaders

Dr. Hans Weber, CEO of TRUMPF Group:

“The future of CNC lies in closed-loop digital twins. Our new Smart Factory in Stuttgart uses real-time data from 10,000 sensors to achieve 99.8% first-pass yield.”

Li Wei, CTO of Shenyang Machine Tool:

“Collaboration with European partners is accelerating our R&D in multi-tasking CNC systems. We aim to launch a 7-axis hybrid machine by Q3 2025.”