| Registro

Top Strategies to Overcome Challenges in Automotive Mold Design

Automotive mold design demands precision, innovation, and problem-solving expertise to address complex manufacturing requirements. Here are key strategies to tackle common challenges while optimizing for efficiency and quality:

Complex Geometry Handling

Use advanced simulation tools (e.g., ANSYS, MoldFlow) to predict material flow, shrinkage, and warpage. This minimizes trial-and-error in creating intricate automotive components like bumpers or dashboards.

Material Selection & Thermal Management

Opt for high-strength alloys or composites to withstand high-pressure injection cycles. Integrate conformal cooling channels to enhance mold cooling efficiency, reducing cycle times and defects.

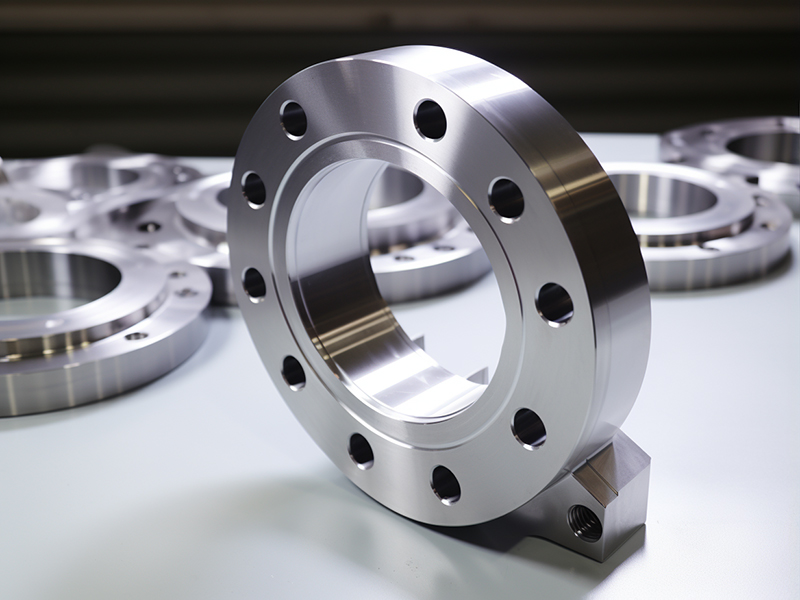

Precision & Surface Finish

Leverage CNC machining and EDM (Electrical Discharge Machining) for micron-level accuracy. Prioritize surface finish quality through polished cavities and texture mapping aligned with automotive standards.

Cost-Effective Solutions

Adopt modular mold designs for flexible production of multiple parts. Utilize 3D printing for rapid prototyping to validate designs before mass production.

By combining advanced simulation, thermal optimization, and agile design practices, manufacturers can overcome hurdles in automotive mold design while ensuring durability, efficiency, and compliance with industry standards.