| Registro

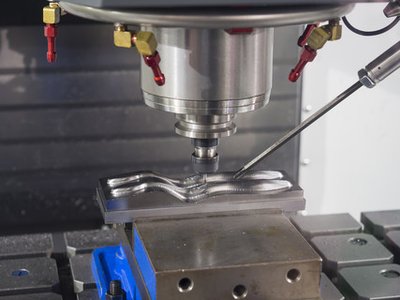

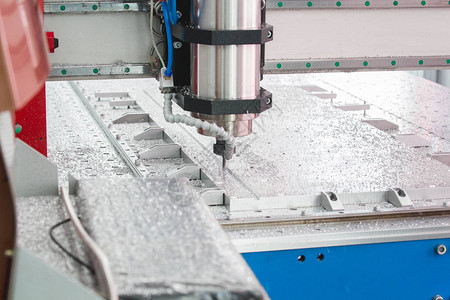

The 5-axis method refers to a type of computer numerical control (CNC) machining that involves movement along five different axes simultaneously to create complex and precise parts. Unlike traditional 3-axis machining, which moves along three linear axes (X, Y, and Z), the 5-axis method adds two additional rotational axes to the system. This allows the machine to perform more intricate movements, enabling the creation of parts with complex geometries that would be difficult or impossible to produce with standard 3-axis machines.

The Five Axes in 5-Axis CNC Machining:

X-axis: Horizontal movement (left and right).

Y-axis: Horizontal movement (forward and backward).

Z-axis: Vertical movement (up and down).

A-axis: Rotational movement around the X-axis (tilting the part or tool).

B-axis: Rotational movement around the Y-axis (tilting the part or tool in a different direction).

How 5-Axis Machining Works:

Tool Positioning: In 5-axis machining, the cutting tool can approach the part from multiple angles without the need to reposition the part itself. This flexibility allows for more complex cuts and detailed features.

Simultaneous Movement: All five axes can move at the same time, making it possible to cut intricate and detailed features with a single setup, reducing the need for multiple tool changes or part repositioning.

How 5-Axis Machining Works:

Tool Positioning: In 5-axis machining, the cutting tool can approach the part from multiple angles without the need to reposition the part itself. This flexibility allows for more complex cuts and detailed features.

Simultaneous Movement: All five axes can move at the same time, making it possible to cut intricate and detailed features with a single setup, reducing the need for multiple tool changes or part repositioning.

Benefits of 5-Axis CNC Machining:

Complex Geometries: It allows for the creation of complex shapes with curved surfaces, undercuts, and intricate angles, which would be difficult for 3-axis machines to achieve.

Higher Precision: Because the part doesn’t need to be moved between different setups, the process is more precise, reducing the risk of errors or misalignments.

Faster Production Time: The ability to machine from multiple angles without re-clamping parts speeds up production time and increases efficiency.

Better Surface Finish: The continuous movement of the tool along various axes ensures a smoother surface finish, reducing the need for secondary finishing operations.

Reduced Tool Wear: By being able to access hard-to-reach areas without repositioning, there’s less wear on tools and machine parts.

Applications of 5-Axis Machining:

Aerospace Industry: Parts with complex contours, such as turbine blades and other critical components, are often made using 5-axis machining.

Automotive Industry: Precision components for engine blocks, suspension parts, and prototypes.

Medical Devices: Surgical instruments, implants, and dental equipment require high precision and often benefit from 5-axis machining.

Mold Making: The method is ideal for creating complex molds and dies with intricate features.

Tooling: Producing high-precision tools, such as cutting tools and jigs.

Types of 5-Axis CNC Machines:

Trunnion Type: The workpiece is mounted on a rotating table (trunnion), which allows the part to tilt around two axes (A and B).

Rotary Table Type: The workpiece is mounted on a rotary table that can rotate around the A and B axes, while the machine's main axis (X, Y, Z) moves the tool.

Tilt-Rotary Type: The machine tool itself tilts and rotates, offering even more flexibility for accessing the part from various angles.